Hello UCONN Students! As you continue to work towards successful degrees in Engineering, Loos wants to share an exciting project & career opportunity with you all.

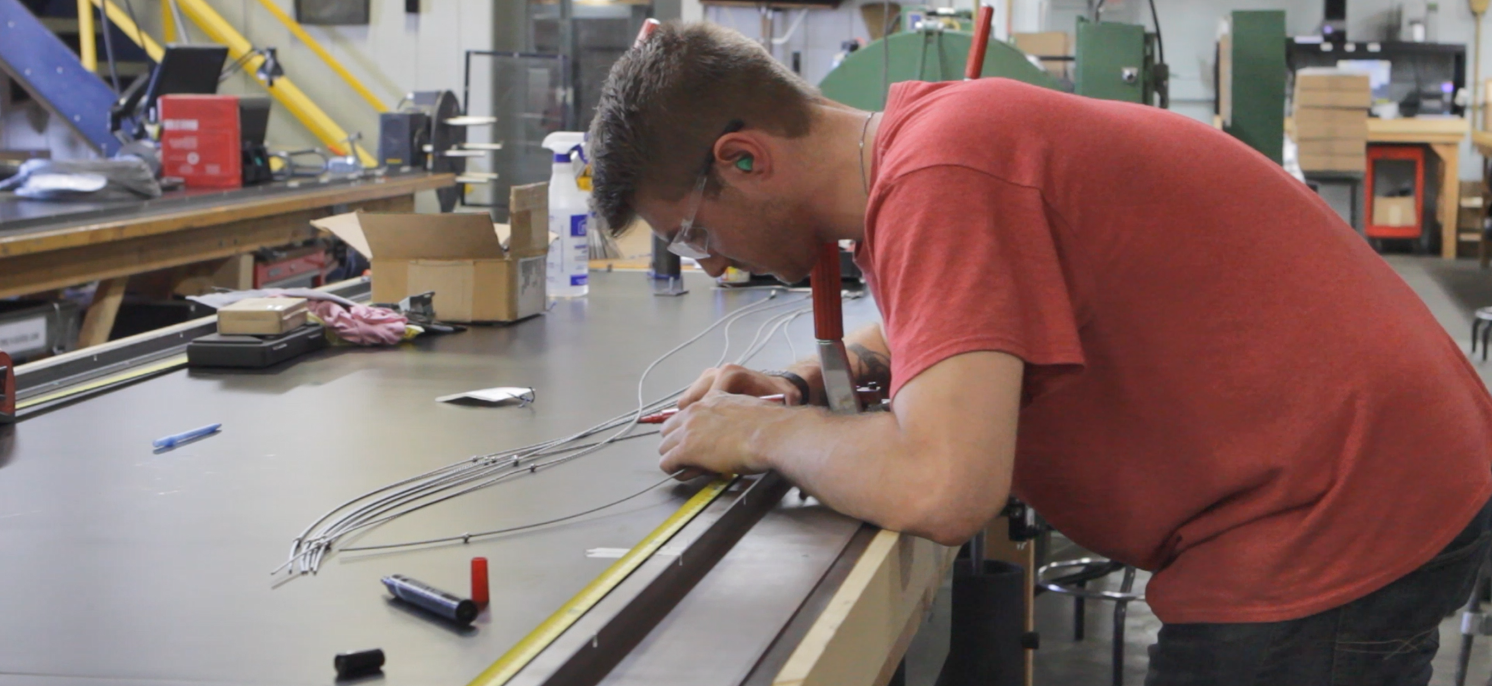

Project 1: Machine Sensing for Manufacturing Optimization

Technical Challenges:

Current equipment available for wire rope stranding are finally offering new technology in terms of sensing and computing on board. In these newer models, the overall process is not changed, however the control systems have been dramatically improved. These improvements eliminate some mechanical issues, and suddenly make available more information about the machines than we have ever had before.

The data presents a real opportunity for our team, but we lack a universal understanding of what this data actually means and how it could be used. Our technical teams lack bandwidth and some of the knowledge required to drive a functional system that converts this datastream into a distilled list of actions to be addressed.

Description of Problem/Project:

Along with this new access to data, we have two challenges ahead.

- How can we make use of the realtime data to enable new insights and drive action for our operation?

- What additional sensing could be employed to fill in the gaps in relevant data streams to improve our understanding of our processes?

Expected Deliverables/Approach:

This would likely require the review of currently available data streams and the potential need to develop a sensor/sensor array to be added to the machine to bolster the analysis. Students would be asked to deliver a package that would tie into the on-board PLC utilizing the an alarm output to stop the machine in event of a failure.

Our first project in the 23/24 school year was discovered a means of detecting a “line-out” condition while the machine is running. We would like to build on this program and investigate formal tie ins to the PLC for the alarm output and any additional sensing capabilities.

Other Considerations:

Specific products are ITAR controlled, but we could work around their inclusion for any data exported from the facility. Students without Greencard/citizenship could be included in the project, but would require vetting and some special treatment to ensure we remove possibility of accidental information export.

Project 2: Wire integrity evaluation in cold drawing of 304/302 SS.

Technical Challenges:

Stainless steel wire used to make stranded cable is drawn, heat treated and stranded within the Pomfret facility. Our products are tested to ensure their performance in the extreme environments they serve.

As testing requirements have increased and new testing instrumentation has become available, we are learning more about the materials in our products. Along with this newfound ability to test and analyze materials, we want to better understand the impact of newly recognized features on the performance of our products.

Current theories are hopeful that an investigation of surface characteristics and/or internal microstructure analysis may offer insights into performance.

Other Considerations:

Specific products are ITAR controlled, but we could work around their inclusion for any data exported from the facility. Students without Greencard/citizenship could be included in the project, but would require vetting and some special treatment to ensure we remove possibility of accidental information export.

Who We Are

For over 60 years, Loos and Company has pioneered and thrived in the highly critical profession of cable and wire rope manufacturing for use in aerospace flight controls, elevators, rigging, and scaffolding where human lives are directly at stake.

Today, Loos & Co. is proud to be a part of Central Wire Group of Companies. Loos manufactures a wide variety of wire, aircraft cable, and wire rope. These products are used in aerospace, military, and commercial applications, including – aircraft flight controls, elevators, fitness equipment, rigging, and scaffolding operations.

We are OEM producers for companies such as Boeing, General Dynamics, and Bombardier.

Today, Loos is proud to be a part of Central Wire Group of Companies. As CWGC, we have 13 manufacturing locations across USA, Canada, and the UK. Browse a full list of our locations on our page here.

Careers

Across our 13 locations, we are actively looking to fill a variety of open positions in various Engineering sectors. We greatly appreciate the opportunity to work with Students in Internship positions to provide an introduction to the manufacturing industry. Additionally, we offer Engineering Students full-time positions to help apply technical skills learnt in school into the workforce. Our full-time positions come with extensive training, competitive wages, and a great list of benefits!

Check out our videos below to see how our Engineers continue to grow & learn new things everyday at Loos!

Unique Employee Journeys

Women in Manufacturing

Pride in Manufacturing Work

Our Recent Projects & Applications

Suicide Prevention Netting

Rescue Hoist Cable

Critical Custom Cable Assemblies

Interested in Our Other Manufacturing Capabilities? Watch the Video Below!

Trusted Partners

A Message from One of Our Top Customers

“Pilatus Aircraft develops and produces the world’s most unique aircraft and relies on the world’s top manufacturers to deliver against exacting Swiss standards. Loos & Co. is our trusted source for precision machined cable end fittings and the highest quality aircraft cable used in our flight control assemblies. Swiss design, made in the USA on Swiss machines… a perfect match.”

Downloadable Resources

Our Certifications

Our Aircraft Control & Military Cable Assemblies are built for all military applications and we are a major supplier to Bombardier, Lockheed Martin, and almost every other major manufacturer of commercial and military aircraft. Loos is one of the few companies in North America qualified to the Department of Defense’s QML-6117 assembly specification. Our finished aerospace assemblies are produced with our MS and AN type fittings. Further, we are licensed by Lockheed Martin to manufacture C-130 B-H Certified Parts for worldwide distribution.

Start Your Career in Manufacturing Today!

Now that you know a little bit about us as a company, we want to hear more about you! Discover our Engineering opportunities on our Careers Page or reach out to our HR Team directly at h[email protected]

We look forward to speaking with you & hope that you are interested in joining our ever-growing Engineering Team here at Central Wire Group of Companies!