At Loos and Company, our CNC Milling and Turning capabilities makes us an industry leader in custom manufacturing capabilities.

Boasting the best equipment in the industry with many years of experience means you can rely on us to deliver precisely what you need, every time. If you have high-volume requirements, we have the answer — our Swiss-Type Lathe machines are made for just that.

Our machining capabilities allow us to meet short lead times, manufacture to exact dimension and specifications, all whilst creating the high quality products you expect from Loos and Co.

Read below to learn about how our Milling and Turning machines allow us to meet our customer’s custom CNC part needs.

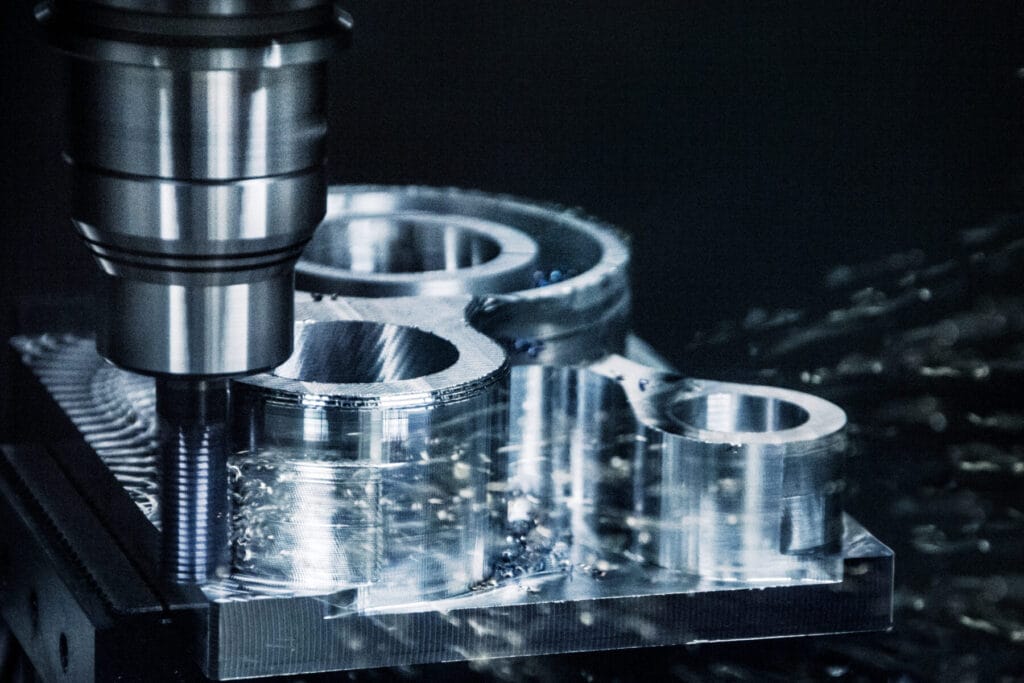

CNC Milling

CNC milling is a machining process controlled by computer that offers a variety of processes and for a diverse selection of materials. We are able to take your 2D or 3D design files, convert them, and then set up and execute the process of creation.

There are many factors to consider when choosing a material (tensile strength, hardness, cost, etc.), and we will work with you to determine the appropriate execution for your application. Key features include:

- High accuracy CNC milling

- 3 and 4-axis precision CNC milling

- Versatile machining for a variety of applications

- Ability to maintain tolerances as small as .001”

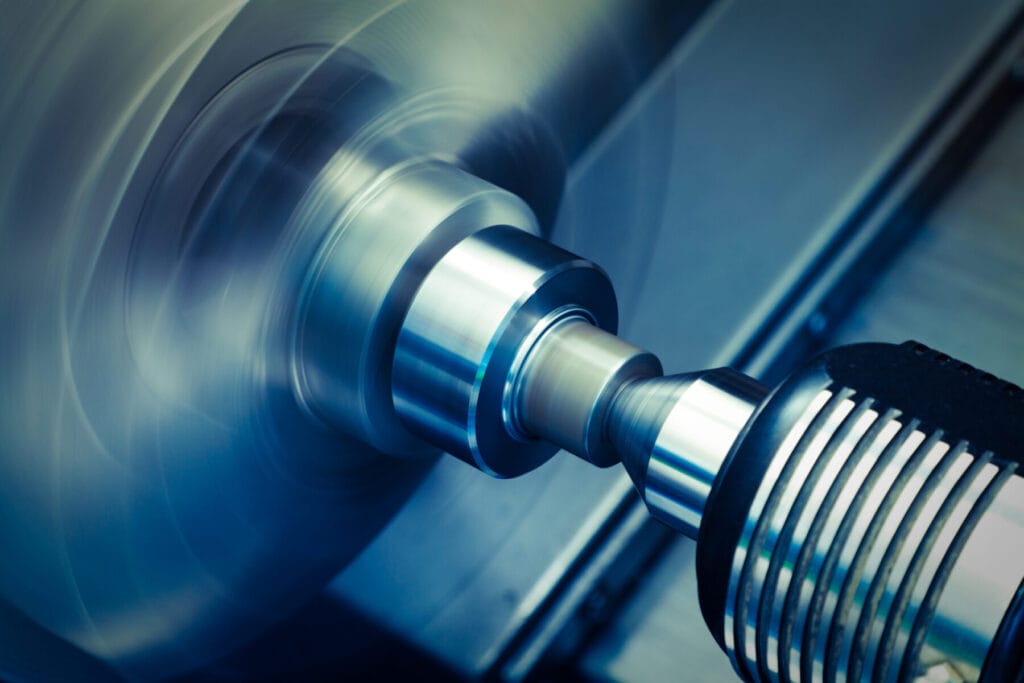

CNC Turning

Whatever your precision turning needs, we are ready for you. Our machining team is highly trained and experienced, capable of meeting and maintaining tolerances as small as .0001”, making us stand out from our competitors. Our shop has experience machining all types of ferrous and non-ferrous material, including stainless steels, carbon steels, brass, aluminum, and exotic metals such as titanium. Key features include:

- Precision turning to +/- 0.0001″

- Cocentric turning

- Multi-axis precision CNC turning

- Multi-spindle CNC turning

- Turning with live tooling